Welcome To Shanghai Rongkun Industrial Equipment Co., Ltd. !

DESCRIPTION

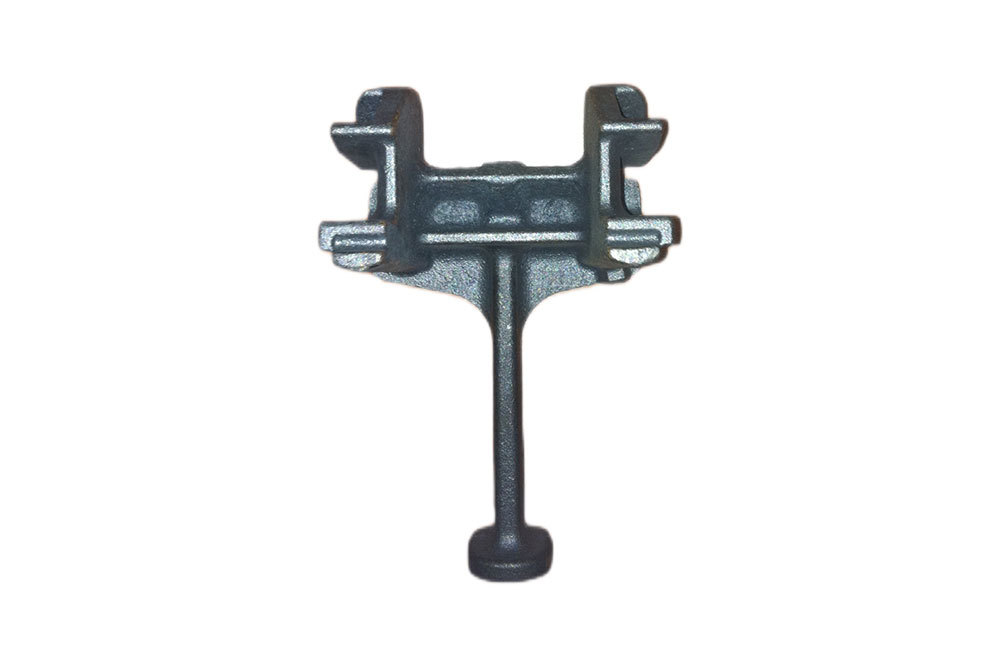

Rail shoulder is a pre-inserted part in a concrete sleeper. It is used together with a rail clip to fix rails. According to different use requirements, rail shoulder can be completed by casting and hot forging.

Casting rail shoulders are pressed in concrete sleeper and assembled with rail clip in order to fasten the rail. The material we use is cast iron, the mechanical property and chemical composition of the rail cast iron shoulder are shown below :

| Material | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) |

| QT400-15(GGG40) | 400 | 250 | 15 |

| QT450-10(GGG45) | 450 | 310 | 10 |

| QT500-7 (GGG50) | 500 | 320 | 7 |

|

|

C |

Si |

Mn |

P |

S |

|

QT400-15 |

3.6-.36 |

3.0-3.2 |

0.5 |

0.07 |

0.02 |

|

Qt450-10 |

3.4-3.9 |

3.7-3.0 |

0.5 |

0.07 |

0.03 |

|

QT500-7 |

3.4-3.8 |

2.5-2.9 |

0.6 |

0.08 |

0.025 |

Hot forging rail shoulder is produced by hot forging and used together with fasteners like bolt and clip, which is put into the concrete sleeper in advance, it is widely used in Russia.

Weld-on shoulder is used for the typical position of rail. This rail cast iron shoulder is welded on flat steel plate instead of the standard tie plate and is produced according to AREA standard.

Designed for use with E style elastic rail clips, the weld on shoulder fastening allows customers to fabricate rail retaining units on both steel sleepers and steel base plates.

According to the AREMA standard, the weld-on rail shoulder is made by hot forging. The production material of weld-on rail shoulder can be low carbon or medium carbon steel.

Keyword:

Rail fasteners

Rail jointing

Rail tie plate

Rail fastening system

Rail turnout

Steel rails

Locomotive parts